This study guide can be used to prepare for the Food

Safety Manager Exam before attending the class. Here

are some tips to help you review:

As you review the study guide use the

sections to help test yourself.

Whenever you see the symbol, remember

it’s an important topic.

FOOD SAFETY MANAGER

CERTIFICATION

Pre-Class Study Guide

How to study before the class and/or exam

1

Chapter 1 - Providing Safe Food

A foodborne illness is a disease transmitted to people through food. An illness is considered an outbreak when:

1. Two or more people have the same symptoms after eating the same food

2. An investigation is conducted by state and local regulatory authorities

3. The outbreak is confirmed by laboratory analysis

Challenges include:

Time and money, language and culture, literacy and education, pathogens, unapproved suppliers, high-risk customers and

staff turnover.

Costs of Foodborne Illness

Loss of customers and sales

Loss of reputation

Negative work exposure

Lower staff morale

Lawsuits and legal fees

Staff missing work

Increased insurance

premiums

Staff retraining

There are 5 top risk factors for foodborne illness:

1. Purchasing food from unsafe sources.

2. Failing to cook food correctly.

3. Holding food at incorrect temperatures.

4. Using contaminated equipment.

5. Practicing poor personal hygiene.

Q. How Does Food Become Unsafe?

1. Time-Temperature Abuse

2. Cross Contamination

3. Poor Personal Hygiene

4. Poor cleaning and sanitizing

Foods Most Likely to Become Unsafe

Servsafe calls these foods, TCS foods. They consist of: Dairy products, eggs, meats, poultry, fish, shellfish, cooked potatoes,

cooked rice, soy and soy products, bean sprouts, cut tomatoes and melons & garlic and oil mixtures.

Q. What is Ready-to-Eat Food?

A. Ready-to-eat food is food that can be eaten without further:

Preparation Washing

Cooking

Ready-to-eat food includes: Cooked food, Washed fruit and vegetables, Deli meat, Bakery items and Sugar, spices, and

seasonings

Some Populations are at a High Risk for Foodborne Illnesses: Elderly people, preschool-age children, and people with

compromised immune systems

2

How Foodborne Illnesses Occur - Unsafe food is the result of these 3 contaminations:

Biological Contaminants

Chemical Contaminants

Physical Contaminants

Bacteria

Viruses

Parasites

Fungi

Cleaners

Sanitizers

Polishes

Metal shavings

Staples

Bandages

Glass

Dirt

Natural Objects (fish bones)

Contaminants come from a variety of places:

Animals we use for food

Air, contaminated water, and dirt

People – Deliberately or Accidentally

People can contaminate food when:

They don’t wash their hands after using the restroom

They are in contact with a person who is sick

They sneeze or vomit onto food or food contact surfaces

They touch dirty food-contact surfaces and equipment and then touch food

3

Chapter 2 - Forms of Contamination

Biological Contaminants

Remember These Terms…

Microorganism: Small, living organism that can be seen only with a microscope

Pathogen: Harmful microorganism and makes people sick when eaten or produce toxins that cause illness

Toxin: Poison

Common symptoms of foodborne illness: Diarrhea, Vomiting, Fever, Nausea, Abdominal cramps, Jaundice (yellowing of skin

and eyes)

Onset times: Depend on the type of foodborne illness can range from 30 minutes to six weeks

Q. What 4 types of pathogens can contaminate food and cause foodborne illness?

A. Bacteria, Viruses, Parasites & Fungi

BACTERIA

Location: Found almost everywhere

Detection: Cannot be seen, smelled, or tasted

Growth: Will grow rapidly if FAT TOM conditions are correct (see page 3)

Prevention: Control time and temperature

Use FATTOM to help you remember the conditions in which bacteria grows rapidly

Food - Most bacteria need nutrients to survive; TCS food supports the growth of bacteria better than other types of food

Acidity - Bacteria grow best in food that contains little or no acid; what Bacteria Need to Grow

Temperature - Bacteria grow rapidly between 41˚F and 135˚F (5˚C and 57˚C; temperature danger zone

Time – Bacteria needs time to grow

Oxygen - Some bacteria need oxygen to grow, while others grow when oxygen isn’t there

Moisture - Bacteria grow well in food with high levels of moisture

Control FAT TOM - The conditions you can control:

Temperature - Keep TCS food out of the temperature danger zone

Time - Limit how long TCS food spends in the temperature danger zone

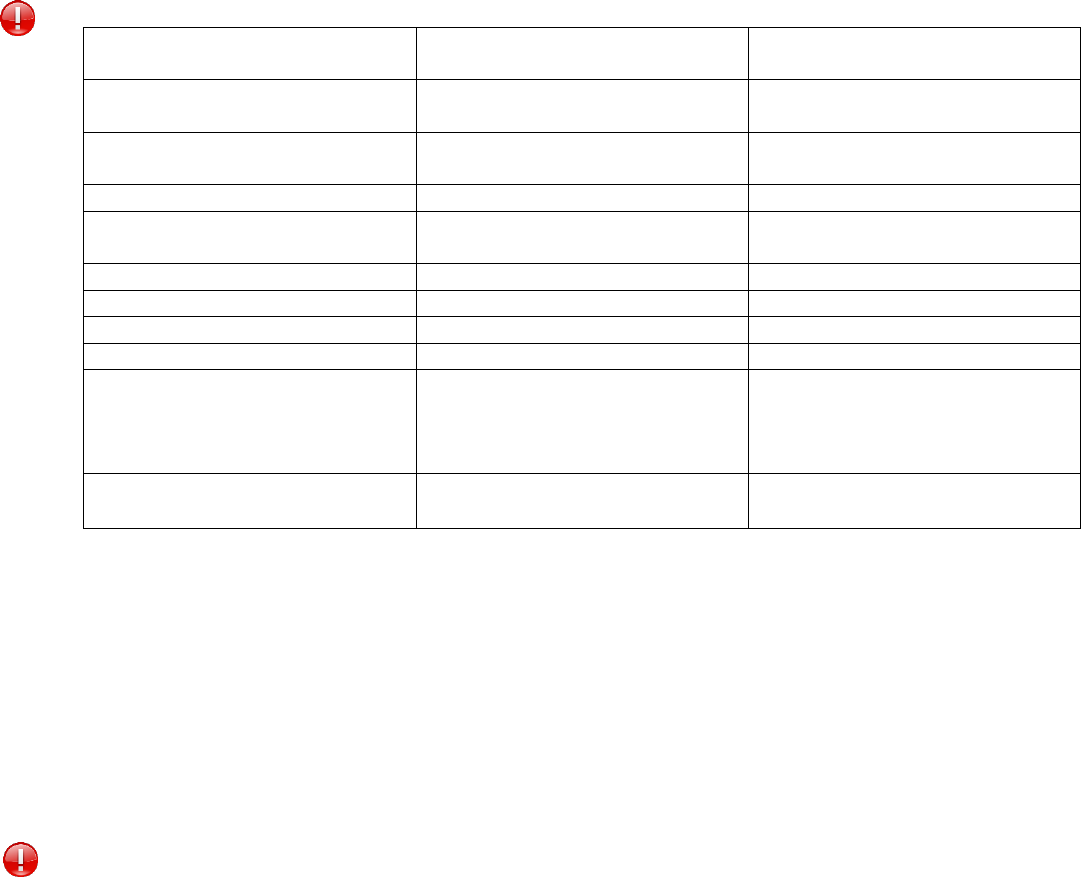

Major Bacteria That Cause Foodborne Illness

The FDA has identified three types of bacteria that cause severe illness and are highly contagious:

Bacteria

Source

Linked Food

Prevention Method

Salmonella Typhi

People

Ready to eat food

Beverages

Wash Hands

Cooking food to min. temp.

Shigella spp.

Human Feces

Hands touching

TCS foods

Produce

Exclude food handlers with

diarrhea

Control flies

Escherichia coli (E-coli)

Intestines of cattle

Ground beef

Produce

Exclude food handlers with

diarrhea

Prevent cross contamination

4

VIRUSES

Location: Carried by human beings and animals, require a living host to grow, do not grow in food and can be transferred

through food and remain infectious in food.

Sources: Food, water, or any contaminated surface and typically occur through fecal-oral routes

Destruction: Not destroyed by normal cooking temperatures, good personal hygiene must be practiced when handling food

and food-contact surfaces, quick removal and cleanup of vomit is important.

Major Viruses that Cause Foodborne Illnesses

Viruses

Source

Linked Food

Prevention Method

Hepatitis A

Human Feces

Ready to eat food

Shellfish

Exclude staff with Hep. A and/or

jaundice

Wash hands

Buy shellfish from reputable

supplier

Norovirus

Human Feces

Ready to eat food

Shellfish

Exclude staff with Norovirus

and/or vomiting or diarrhea

Wash hands

Buy shellfish from reputable

supplier

PARASITES

Location: Require a host to live and reproduce

Source: Seafood, wild game, and food processed with contaminated water, such as produce

Prevention: Purchase food from approved, reputable suppliers, cook food to required minimum internal temperatures and

fish that will be served raw or undercooked, must be frozen correctly by the manufacturer.

FUNGI

Location: Yeasts, molds, and mushrooms. Some molds and mushrooms produce toxins, throw out moldy food, unless mold is

a natural part of the food, purchase mushrooms from approved, reputable suppliers.

Biological Toxins: Naturally occur in certain plants, mushrooms, and seafood

Seafood toxins: Produced by pathogens found on certain fish (Tuna, bonito, mahi-mahi). Histamine produced when fish is

time-temperature abused. Occurs in certain fish that eat smaller fish that have consumed the toxin. Barracuda, snapper,

grouper, amberjack i.e Ciguatera toxin.

Illness: Symptoms and onset times vary with illness. People will experience illness within minutes

General symptoms: Diarrhea or vomiting, neurological symptoms, tingling in extremities, reversal of hot and cold sensations,

flushing of the face and/or hives, difficulty breathing and heart palpitations.

Chemical Contaminants

Sources: Certain types of kitchenware and equipment (copper, pewter, zinc and galvanized pans when used to prepare acidic

food- Toxic Metal Poisoning), cleaners, sanitizers, polishes, machine lubricants, and pesticides and deodorizers, first-aid

products, health and beauty products.

Symptoms: Vary depending on chemical consumed, illnesses occur within minutes, vomiting and diarrhea are typical

Prevention: Only use chemicals approved for use in foodservice operations, purchase chemicals from approved,

reputable suppliers and store chemicals away from prep areas, food-storage areas, and service areas.

5

Physical Contaminants

Sources: Common objects that get into food (Metal shavings from cans, wood, fingernails , staples, bandages, glass, jewelry,

dirt)

Symptoms: Mild to fatal injuries are possible, cuts, dental damage, and choking, bleeding and pain

Prevention: Purchase food from approved, reputable suppliers, closely inspect food received

A.L.E.R.T

Deliberate Contamination of Food - Groups who may attempt to contaminate food:

Terrorists or activists

Disgruntled current or former staff

Vendors

Competitors

FDA defense tool: A.L.E.R.T.

Assure Make sure products received are from safe sources

Look Monitor the security of products in the facility

Employees Know who is in your facility

Reports Keep information related to food defense accessible

Threat Develop a plan for responding to suspicious activity or a threat to the operation

Steps to Respond to a Foodborne-Illness Outbreak

1. Gather information

2. Notify authorities

3. Segregate product

4. Document information

5. Identify staff

6. Cooperate with authorities

7. Review procedures

Food Allergens

Food allergen: A protein in a food or ingredient some people are sensitive to. These proteins occur naturally.

Allergy symptoms: Nausea, wheezing or shortness of breath, hives or itchy rashes, swelling of the body, including the face,

eyes, hands, or feet, vomiting and/or diarrhea, abdominal pain.

Allergic reactions: Symptoms can become serious quickly, a severe reaction, called anaphylaxis, can lead to death

Common food allergens:

Milk

Eggs

Fish

Shellfish

Wheat

Soy

Peanuts

Tree nuts

Prevent Allergic Reactions

Service staff: Describe how the dish is prepared, identify ingredients, suggest simple menu items, hand-deliver food to

customers with food allergies.

Kitchen staff: Avoid cross-contact with food items containing allergens in the kitchen

6

The Safe Food Handler

Food handlers can contaminate food when they:

Have a foodborne illness

Have wounds that contain a pathogen

Sneeze or cough

Have contact with a person who is sick

Touch anything that may contaminate their hands

and don’t wash them

Have symptoms such as diarrhea, vomiting, or

jaundice

Actions that can contaminate food:

Scratching the scalp

Running fingers through hair

Wiping or touching the nose

Rubbing an ear

Touching a pimple or infected wound

Wearing a dirty uniform

Coughing or sneezing into the hand

Spitting in the operation

Managers must focus on the following:

Creating personal hygiene policies

Training food handlers on personal hygiene

policies

Modeling correct behavior at all times

Supervising food safety practices

Revising personal hygiene policies regularly

Work Attire - Food handlers must:

Wear a clean hat or other hair restraint

Wear clean clothing daily

Remove aprons when leaving food-preparation

areas

Remove jewelry from hands and arms before

prepping food.

Eating, Drinking, Smoking, and Chewing Gum or Tobacco

Food handlers must not eat, drink, smoke, or chew gum or tobacco when:

Prepping or serving food

Working in prep areas

Working in areas used to clean utensils and equipment

Hand washing and Glove Use

Q. What is the right way to wash your hands?

A.

1. Wet hands with running water as hot as you can comfortably stand (at least 100°F/38°C)

2. Apply soap

3. Vigorously scrub hands and arms for ten to fifteen seconds Clean under fingernails and between fingers

4. Rinse thoroughly under running water

5. Dry hands and arms with a single-use paper towel or warm-air hand dryer Use a paper towel to turn off the faucet.

Food handlers must wash their hands before they start work and after:

Using the restroom

Handling raw meat, poultry, and seafood (before

and after)

Touching the hair, face, or body

Sneezing, coughing, or using a tissue

Eating, drinking, smoking, or chewing gum or

tobacco

Handling chemicals that might affect food safety

7

Food handlers must wash their hands after:

Taking out garbage

Clearing tables or busing dirty dishes

Touching clothing or aprons

Handling money

Leaving and returning to the kitchen/prep area.

Handling service animals or aquatic animals

Touching anything else that may contaminate

hands

Something else you should know…

Hand antiseptics: Must comply with the CFR and FDA standards and must NEVER be used in place of hand washing

Requirements for food handlers: Keep fingernails short and clean, do NOT wear false nails, do NOT wear nail polish.

Infected Wounds or Cuts: Contain pus and must be covered

Single-use gloves:

Should be used when handling ready-to-eat food (Except when washing produce and when handling ready-to-eat

ingredients for a dish that will be cooked)

Must NEVER be used in place of hand washing

Must NEVER be washed and reused

Must fit correctly

When to change gloves:

As soon as they become dirty or torn

Before beginning a different task

After an interruption i.e phone call

After handling raw meat, seafood, or poultry and

before handling ready-to-eat food

Bare hand contact with ready-to-eat food must be avoided: Some jurisdictions allow it but require: Policies on staff health,

training in hand washing and personal hygiene practices. NEVER handle ready-to-eat food with bare hands when you primarily

serve a high-risk population

Handling Staff Illnesses

If

Then

The food handler has sore throat and fever

Restrict from working with food

Exclude from work if serving a high risk population

The food handler has vomiting and/or diarrhea

Exclude the food handler from the operation

The food handler has jaundice

Report to the regulatory authority

Exclude the food handler from the operation

The food handler has been diagnosed with a foodborne

illness

Work with a regulatory authority

Exclude the food handler from the operation

8

Chapter 3 - An Introduction

Q. How do you keep food safe throughout the flow of food?

A. Prevent cross-contamination & prevent time-temperature abuse

Preventing Cross-Contamination

Separate equipment: Use separate equipment for each type of food

Clean and sanitize: Clean and sanitize all work surfaces, equipment, and utensils after each task

Prep food at different times: Prepare raw meat, fish, and poultry at different times than ready-to-eat food

Buy prepared food: Buy food items that don’t require much prepping or handling

Preventing Time-Temperature Abuse

Time-temperature control: Food held in the range of 41F and 135°F (5 and 57°C) has been time-temperature abused

Avoid time-temperature abuse: Monitor time and temperature. Make sure the correct kinds of thermometers are available.

Regularly record temperatures and the times they are taken. Minimize the time that food spends in the temperature danger

zone. Take corrective actions if time-temperature standards are not met

Monitoring Time and Temperature – Using Thermometers

Remember these terms…

Bimetallic stemmed thermometer – Most basic thermometer

Thermocouples and Thermistors – measures through a metal probe, displays temps digitally and has sensing area on the tip

of the probe.

Infared thermometers – Used to measure surface area. Follow manufactures guidelines.

Time-temperature indicators (TTI): Monitor both time and temperature, are attached to packages by the supplier

Maximum registering tape: Indicates the highest temperature reached during use

Thermometer Guidelines: Wash, rinse, sanitize, and air-dry thermometers before and after using them. Calibrate them before

each shift to ensure accuracy. Only use glass thermometers if they are enclosed in a shatterproof casing

When using thermometers: Insert the thermometer stem or probe into thickest part of the product

(usually the center). Take more than one reading in different spots. Wait for the thermometer reading to steady before

recording the temperature

9

Chapter 4 - Purchasing, Receiving, and Storage

Purchasing and Receiving

Purchase food from approved, reputable suppliers: Have been inspected and meet all applicable local, state, and federal

laws.

Arrange deliveries so they arrive: When staff has enough time to do inspections and when they can be correctly received.

Receiving principles: Make specific staff responsible for receiving and train them to follow food safety guidelines. Store items

promptly after receiving.

Key drop deliveries: Supplier is given after-hour access to the operation to make deliveries.

Deliveries must meet the following criteria

Be inspected upon arrival at the operation

Be from an approved source

Have been placed in the correct storage location

to

maintain the required temperature

Have been protected from contamination in

storage

Is NOT contaminated

Is honestly presented

Rejecting deliveries

Separate rejected items from accepted items

Tell the delivery person what is wrong with the

item

Get a signed adjustment or credit slip before

giving

the rejected item to the delivery person

Log the incident on the invoice or receiving

document

Handling Recalls

Identify the recalled food items

Remove the item from inventory, and place it in a

secure and appropriate location

Store the item separately from food, utensils,

equipment, linens, and single-use items

Label the item in a way that will prevent it from

being placed back in inventory

Inform staff not to use the product

Refer to the vendor’s notification or recall notice

to determine what to do with the item

Checking the temperature of received foods

Meat Poultry and Fish – Insert probe into the thickest part of the meat

ROP Food – Insert the probe between2 packages or fold package around the probe

Other packaged food – Open the package and insert the probe into the food

Temperature criteria for deliveries:

Cold TCS food: Receive at 41°F (5°C) or lower, unless otherwise specified

Live shellfish: Receive oysters, mussels, clams, and scallops at an air temperature of 45°F (7°C) and an internal

temperature no greater than 50°F (10°C)

Shucked shellfish: Receive at 45°F (7°C) or lower

Shell eggs: Receive at an air temperature of 45°F (7°C) or lower

Milk: Receive at 45°F (7°C) or lower

Hot TCS food: Receive at 135°F (57°C) or higher

Frozen food: Receive frozen solid

10

Reject delivery if there is:

Evidence of thawing and refreezing

Fluids or water stains in case bottoms or on

packaging

Ice crystals or frozen liquids on the food or

packaging

Tears, holes, or punctures in packaging

Cans with swollen ends, rust, or dents

Bloating or leaking (ROP food)

Broken cartons or seals

Dirty and discolored packaging

Leaks, dampness, or water stains

Signs of pests or pest damage

Expired use-by/expiration dates

Evidence of tampering

Required documents to be collected when receiving food:

- Shellfish must be received with shellstock identification tags. Tags indicate when and where the shellfish were harvested.

Must be kept on file for 90 days from the date the last shellfish was used from its delivery container

- Fish that will be eaten raw or partially cooked. Documentation must show the fish was correctly frozen before being

received. Keep documents for 90 days from the sale of the fish

- Farm raised fish. Must have documentation stating the fish was raised to FDA standards. Keep documents for 90 days from

the sale of the fish

Assessing food quality:

Appearance: Reject food that is moldy or has an abnormal color

Texture: Reject meat, fish, or poultry if it is slimy, sticky, or dry. It has soft flesh that leaves an imprint when touched.

Odor: Reject food with an abnormal or unpleasant odor

Storage

Labeling food for use on-site:

All items not in their original containers must be labeled

Food labels should include the common name of the food or a statement that clearly and accurately identifies it

It is not necessary to label food if it clearly will not be mistaken for another item

Date marking:

Ready-to-eat TCS food must be marked if held for

longer than 24 hours.

Date mark must indicate when the food must be

sold, eaten, or thrown out

Ready-to-eat TCS food can be stored for only

seven days if it is held at 41°F (5°C) or lower

The count begins on the day that the food was

prepared or a commercial container

was opened. For example, potato salad prepared

and stored on October 1 would have a discard

date of October 7 on the label

Some operations write the day or date the food

was prepared on the label. Others write the use-

by day or date on the label

11

Temperatures:

Store TCS food at an internal temperature of 41°F

(5°C) or lower or 135°F (57°C) or higher

Store frozen food at temperatures that keep it

frozen

Make sure storage units have at least one air

temperature measuring device. It must be

accurate to +/- 3°F or +/- 1.5°C

Place the device in the warmest part of

refrigerated units, and the coldest part of hot-

holding units

Do NOT overload coolers or freezers

Prevents airflow

Makes unit work harder

Frequent opening of the cooler lets warm air

inside, which can affect food safety

Use open shelving

Lining shelving restricts circulation

Monitor food temperatures regularly

Randomly sample food temperatures

FIFO

One way to rotate products correctly is to follow FIFO

1. Identify the food item’s use-by or expiration date

2. Store items with the earliest use-by or expiration

dates in front of items with later dates

3. Once shelved, use those items stored in front first

4. Throw out food that has passed its

manufacturer’s use-by or expiration date

Preventing Cross-Contamination While Storing Food

Store all items in designated storage areas

Store items away from walls and at least six inches (15 centimeters) off the floor

Store single-use items in original packaging

Store food in containers intended for food

Use containers that are durable, leak proof, and able to be sealed or covered

NEVER use empty food containers to store chemicals; NEVER put food in empty chemical containers

Keep all storage areas clean and dry

Clean up spills and leaks immediately

Clean dollies, carts, transporters, and trays often

Store food in containers that have been cleaned and sanitized

Store dirty linens in clean, nonabsorbent containers or washable laundry bags

Store food items in the following top-to-bottom order

a. Ready-to-eat food

b. Seafood

c. Whole cuts of beef and pork

d. Ground meat and ground fish

e. Whole and ground poultry

This storage order is based on the minimum internal cooking temperature of each food

Food should be stored in a clean, dry location away from dust and other contaminants

To prevent contamination, NEVER store food in these areas:

Locker rooms or dressing rooms

Restrooms or garbage rooms

Mechanical rooms

Under unshielded sewer lines or leaking water

lines

Under stairwells

12

Chapter 5 - Preparation, Thawing, Cooking, Cooling and Reheating

Prepping

When prepping food:

Only remove as much food from the cooler as you can prep in a short period of time

Return prepped food to the cooler or cook it as quickly as possible

Make sure workstations, cutting boards, and utensils are clean and sanitized

Prepping Specific Foods

Produce – Make sure it doesn’t touch surfaces exposed to raw meats, poultry or seafood, wash produce thoroughly and when

soaking or storing in water do not mix different items or multiple batches of the same item. Refrigerate sliced melons and do

not serve raw seed sprouts to a high risk population.

Egg and Egg Mixtures – Handle pooled eggs with care by cooking promptly or storing at 41°F or lower. Clean and sanitize

between batches. Note: For high risk populations use pasteurized eggs if they are pooled or not fully cooked.

Salads containing TCS Foods – Make sure leftover TCS ingredients have been handled safely.

Ice – Never use ice as an ingredient if it was used to keep food cold. Transfer ice using clean and sanitized scoops. Store ice

scoops outside ice machines. NEVER use glass to scoop ice.

Preparation Practices That Have Special Requirements. You need a variance if prepping food in these ways:

Packaging fresh juice on-site for sale at a later

time, unless the juice has a warning label

Smoking food to preserve it but not to enhance

flavor

Using food additives or components to preserve

or alter food so it no longer needs time and

temperature control for safety

Curing food

Packaging food using a reduced-oxygen packaging (ROP) method

Sprouting seeds or beans

Offering live shellfish from a display tank

Custom-processing animals for personal use (i.e. dressing a deer)

Thawing

Q. What are the 4 Acceptable methods for thawing food?

Answers

1. Thaw food in a cooler, keeping its temperature at 41°F (5°C) or lower

2. Submerge food under running water at 70°F (21°C) or lower

3. Thaw food in a microwave, only if cooked immediately after thawing

4. Thaw as part of the cooking process

13

Cooking Food

When cooking TCS food, the internal portion must: Reach the required minimum internal temperature and hold that

temperature for a specific amount of time.

When checking temperatures: Pick a thermometer with a probe that is the correct size for the food and check the

temperature in the thickest part of the food.

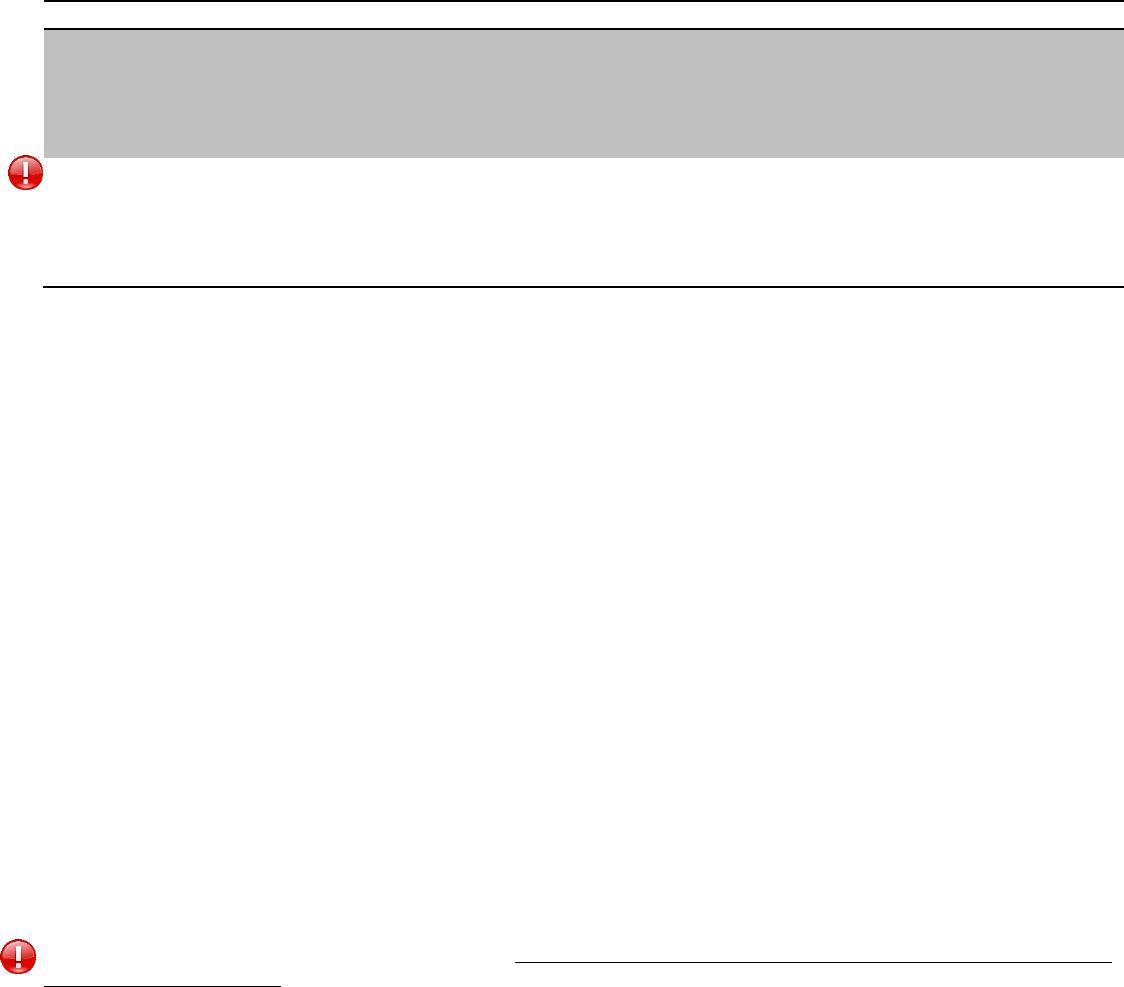

Cooking Requirements for Specific Food

Food

Minimum Internal Cooking

Temperature

Length of Time at this Temperature

Poultry: (including whole or ground

chicken, turkey,and duck)

165°F (74°C)

15 seconds

Ground Meat (including beef, pork,

other meat)

155°F (68°C)

15 seconds

Injected Meat

155°F (68°C)

15 seconds

Pork, Beef, Veal, Lamb

Steaks/Chops:145°F (63°C)

Roasts: 145°F (63°C)

15 seconds

4 minutes

Fish

145°F (63°C)

15 seconds

Ground, chopped, minced fish

155°F (68°C)

15 seconds

Eggs for immediate service

145°F (63°C)

15 seconds

Eggs that will be hot-held

155°F (68°C)

15 seconds

Commercially processed, ready-to-

eat food that will be hot-held for

service (cheese sticks, fried

vegetables, chicken wings, etc.)

135°F (57°C)

15 seconds

TCS Food in a Microwave

Meat, Seafood, Poultry and Eggs.

165°F (74°C)

15 seconds

Guidelines for microwave cooking: Cover food, rotate or stir it halfway through cooking, let it stand for at least two minutes

after cooking and check the temperature in at least two places to make sure the food is cooked through.

If partially cooking meat, seafood, poultry, or eggs or dishes containing these items:

NEVER cook the food longer than 60 minutes

during initial cooking

Cool the food immediately after initial cooking

Freeze or refrigerate the food after cooling it

Heat the food to at least 165˚F (74˚C) for 15

seconds before selling or serving it

Cool the food if it will not be served immediately

or held for service

Consumer Advisories - If your menu includes raw or undercooked TCS items, you must:

Note it on the menu next to the item

Advise customers who order this food of the

increased risk of foodborne illness

Post a notice in the menu

Provide this information using brochures, table

tents, or signs

Consumer Advisories - The FDA advises against offering these items on a children’s menu if they are raw or undercooked:

Meat, Poultry, Seafood and Eggs.

Operations That Mainly Serve High-Risk Populations must NEVER serve: Raw seed sprouts or Raw or undercooked eggs,

meat, or seafood i.e Over-easy eggs, Raw oysters on the half shell, Rare hamburgers.

14

Cooling Food

Cool food from 135˚F to 70˚F (57˚C to 21˚C) within two hours: then from 70˚F to 41˚F within 4 hours: The total cooling time

cannot be longer than six hours

Before cooling food, start by reducing its size: Cut larger items into smaller pieces. Divide large containers of food into

smaller containers or shallow pans

Methods for cooling food safely and quickly:

Place food in an ice-water bath

Stir it with an ice paddle

Place it in a blast chiller

Reheating Food

Food reheated for immediate service: Can be reheated to any temperature if it was cooked and cooled correctly

Food reheated for hot-holding: Must be reheated to an internal temperature of 165°F (74°C) for 15 seconds within two hours.

Reheat commercially processed and packaged ready-to-eat food to an internal temperature of at least 135°F (57°C)

Remember…

Food must be thrown out in the following situations

When it is handled by staff who have been restricted or excluded from the operation due to illness

When it is contaminated by hands or bodily fluids from the nose or mouth

When it has exceeded the time and temperature requirements designed to keep food safe

15

Chapter 6 – Service

Holding Food

Food Holding Temperatures:

Hold TCS food at the correct temperature - Hot food: 135°F(57°C) or higher - Cold food: 41°F(5°C) or lower

Check temperatures at least every four hours

Throw out food not at 41°F (5°C) or lower

Check temperatures every two hours to leave time for corrective action

NEVER use hot-holding equipment to reheat food unless it’s designed for it

Reheat food correctly, and then move it into a holding unit

Q. Can you Hold Food without Temperature Control?

Answer.

Cold food can be held without temperature control for up to six hours if:

It was held at 41°F (5°C) or lower before removing

it from refrigeration

It does not exceed 70°F (21°C) during service -

Throw out food that exceeds this temperature

It has a label specifying: Time it was removed from

refrigeration and time it must be thrown out

It is sold, served, or thrown out within six hours

Hot food can be held without temperature control for up to four hours if:

It was held at 135°F (57°C) or higher before removing it from temperature control

It has a label specifying when the item must be thrown out

It is sold, served, or thrown out within four hours

Serving Food

Prevent contamination when serving food:

Wear single-use gloves whenever handling ready-

to-eat food. As an alternative use spatulas, tongs,

deli sheets, or other utensils

Use clean and sanitized utensils for serving

Use separate utensils for each food

Clean and sanitize utensils after each task

At minimum, clean and sanitize them at least once

every four hours

Store serving utensils correctly between uses

On a clean and sanitized food-contact surface

In the food with the handle extended above the

container rim

Preset Tableware - If you preset tableware: Prevent it from being contaminated; Wrap or cover the items

Re-serving Food - NEVER re-serve:

Food returned by one customer to another

customer

Uncovered condiments

Uneaten bread

Plate garnishes

16

Self Service Areas

Self-Service Areas Requirements

Use sneeze guards - Must be located 14" (36cm)

above the counter, must extend 7" (18cm) beyond

the food

Identify all food items - Label food, place salad

dressing names on ladle handles

Keep hot food at 135°F (57°C) or higher

Keep cold food at 41°F (5°C) or lower

Keep raw meat, fish, and poultry separate from

ready-to-eat food

Do NOT let customers refill dirty plates or use

dirty utensils at self-service areas

Stock food displays with the correct utensils for

dispensing food

Do NOT use ice as an ingredient if it was used to

keep food or beverages cold

Labeling Bulk Food in Self-Service Areas

Make sure the label is in plain view of the customer

Include the manufacturer or processor label provided with the food

A label is not needed for bulk unpackaged food, such as bakery products, if:

The product makes no claim regarding health or

nutrient content

No laws requiring labeling exist

The food is manufactured or prepared on the

premises

The food is manufactured or prepared at another

regulated food operation or processing plant

owned by the same person

Off-Site Service

When delivering food off-site:

Use insulated, food-grade containers designed to stop food from mixing, leaking, or spilling

Clean the inside of delivery vehicles regularly

Check internal food temperatures

Label food with a use-by date and time, and reheating and service instructions

Make sure the service site has the correct utilities

Store raw meat, poultry, and seafood, and ready-to-eat items separately

Vending Machines - To keep vended food safe:

Check product shelf life daily

Keep TCS food at the correct temperature

Dispense TCS food in its original container

Wash and wrap fresh fruit with edible peels

before putting it in the machine

17

Chapter 7 - Food Safety Management Systems

What is a Food safety management system: Group of practices and procedures intended to prevent foodborne illness.

Actively controls risks and hazards throughout the flow of food

These are the foundation of a food safety management system:

Personal hygiene program

Food safety training program

Supplier selection and specification

program

Quality control and assurance program

Cleaning and sanitation program

Standard operating procedures (SOPs)

Facility design and equipment

maintenance program

Pest control program

Active Managerial Control

Focuses on controlling the five most common risk factors for foodborne illness:

1. Purchasing food from unsafe sources

2. Failing to cook food adequately

3. Holding food at incorrect temperatures

4. Using contaminated equipment

5. Practicing poor personal hygiene

There are many ways to achieve active managerial control in the operation:

Training programs

Manager supervision

Incorporation of standard operating procedures (SOPs)

HACCP

These are critical to the success of active managerial control:

Monitoring critical activities in the operation

Taking the necessary corrective action when required

Verifying that the actions taken control the risks factors

HACCP – Hazard Analysis Critical Control Point

The HACCP approach:

HACCP is based on identifying significant biological, chemical, or physical hazards at specific points within

a product’s flow through an operation

Once identified, hazards can be prevented, eliminated, or reduced to safe levels

To be effective, a HACCP system must be based on a written plan:

It must be specific to each facility’s menu, customers, equipment, processes, and operations

A plan that works for one operation may not work for another

18

The 7 HACCP principles:

1. Conduct a hazard analysis

2. Determine critical control points (CCPs)

3. Establish critical limits

4. Establish monitoring procedures

5. Identify corrective actions

6. Verify that the system works

7. Establish procedures for record keeping

and documentation

These specialized processing methods require a variance and may require a HACCP plan:

Smoking food as a method to preserve it (but not

to enhance flavor)

Using food additives or components such as

vinegar to preserve or alter food so it no longer

requires time and temperature control for safety

Curing food

Custom-processing animals

Packaging food using ROP methods including

Treating (e.g. pasteurizing) juice on-site and

packaging it for later sale

Sprouting seeds or beans

19

Chapter 8 - Safe Facilities and Pest Management

Facility Requirements

Interior Requirements for a Safe Operation - Floors, walls, and ceilings:

Materials must be smooth and durable for easier cleaning

Must be regularly maintained

Foodservice equipment must meet these standards if it will come in contact with food:

Nonabsorbent, smooth, and corrosion resistant

Easy to clean

Durable

Resistant to damage

Floor-mounted equipment must be either:

Mounted on legs at least 6 inches (15 cm) high

Sealed to a masonry base

Tabletop equipment should be either:

Mounted on legs at least 4inches (10 cm) high

Sealed to the countertop

Once equipment has been installed:

It must be maintained regularly

Only qualified people should maintain it

Set up a maintenance schedule with your supplier or manufacturer

Check equipment regularly to make sure it is working correctly

Dishwashers must be installed:

So they are reachable and conveniently located

In a way that keeps utensils, equipment, and other food-contact services from becoming contaminated

Following manufacturer’s instructions

Handwashing stations must be conveniently located and are required in:

Restrooms or directly next to them

Food-prep areas

Service areas

Dishwashing areas

Handwashing stations must have:

Hot and cold running water

Soap

A way to dry hands

Garbage container

Signage

Acceptable sources of drinkable water:

Approved public water mains

Regularly tested and maintained private sources

Closed, portable water containers

Water transport vehicles

Remember these terms…

Cross-connection - Physical link between safe water and dirty water from: Drains, Sewers or Other wastewater sources

Backflow - Reverse flow of contaminants through a cross-connection into the drinkable water supply – Prevent using a

Vaccum Break or Air gap.

Backsiphonage - A vacuum created in the plumbing system that sucks contaminants back into the water supply

20

Lighting - Consider the following when installing and maintaining lighting:

Different areas of the facility have different lighting intensity requirements

Local jurisdictions usually require prep areas to be brighter than other areas

All lights should have shatter-resistant light bulbs or protective covers

Replace burned out bulbs with correct size bulbs

Ventilation systems: Must be cleaned and maintained to prevent grease and condensation from building up on walls and

ceilings.

Garbage: Remove from prep areas as quickly as possible and clean the inside and outside of containers frequently.

Indoor containers must be: Leak proof, waterproof, and pest proof, easy to clean and covered when not in use.

Designated storage areas: Store waste and recyclables separately from food and food-contact surfaces. Storage must not

create a nuisance or a public health hazard

Outdoor containers must: Be placed on a smooth, durable nonabsorbent surface, have tight-fitting lids, be covered at all

times and have their drain plugs in place.

Emergencies That Affect the Facility

Imminent health hazard: A significant threat or danger to health or requires immediate correction or closure to prevent injury

Possible imminent health hazards: Electrical power outages, fire, flood and sewage backups.

How to respond to a crisis affecting the facility:

1. Determine if there is a significant risk to the safety or security of your food.

2. If the risk is significant stop service then notify the local regulatory authority.

3. Decide how to correct the problem

4. Establish time-temperature control

5. Clean and sanitize surfaces

6. Verify water is drinkable

7. Reestablish physical security of the facility

Pest Management

Q. What are the 3 rules of pest prevention?

Answer.

1. Deny pests access to the operation

2. Deny pests food, water, and shelter

3. Work with a licensed Pest Control Operator (PCO)

To keep pests from entering with deliveries:

Check deliveries before they enter the operation

Refuse shipments if pests or signs of pests

(egg cases, body parts) are found

Pest Prevention - Make sure all of the points where pests can access the building are secure:

Screen windows and vents

Seal cracks in floors and walls, and around pipes

Install air curtains (also called air doors or fly fans) above or alongside doors

21

Deny pests shelter:

Throw out garbage quickly and correctly

Keep containers clean and in good condition

Keep outdoor containers tightly covered

Clean up spills around containers immediately

Store recyclables correctly

Keep recyclables in clean, pest-proof containers

Keep containers as far away from the building as

regulations allow

Store food and supplies quickly and correctly

Keep them away from walls and at least six inches

(15 cm) off the floor

Rotate products (FIFO) so pests cannot settle and

breed

Clean the operation thoroughly

Clean up food and beverage spills immediately

Clean break rooms after use

Keep cleaning tools and supplies clean and dry

Contact your PCO immediately if you see these or any other pest-related problems:

Feces

Nests

Damage on products, packaging, and the facility

itself

22

Chapter 9 - Cleaning and Sanitizing

Using Cleaners and Sanitizers

Cleaners must be:

Stable and noncorrosive

Safe to use

When using them:

Follow manufacturers’ instructions

Do NOT use one type of detergent in place of another unless the intended use is the same

Surfaces can be sanitized using heat or chemicals:

Heat

The water must be at least 171F°(77°C)

Immerse the item for 30 seconds

Chemicals

Chlorine

Iodine

Quats

Chemical Sanitizing

Food-contact surfaces can be sanitized by either:

Soaking them in a sanitizing solution

Rinsing, swabbing, or spraying them with a sanitizing solution

The following factors can change the effectiveness of the sanitizer:

Concentration: Sanitizers should be mixed with water to the correct concentration

Not enough sanitizer may make the solution weak and useless

Too much sanitizer may make the solution too strong, unsafe, and corrode metal

Check concentration with a test kit and make sure it is designed for the sanitizer used. Check the concentration often.

Change the solution when it’s dirty or the concentration is too low.

Temperature: Follow manufacturer’s recommendations for the correct temperature

Contact time: The sanitizer must make contact with the object for a specific amount of time. Minimum times differ

for each sanitizer.

Water hardness and pH: Find out what your water hardness and pH is from your municipality. Work with your

supplier to identify the correct amount of sanitizer to use.

Guidelines for the Effective Use of Sanitizers

Chlorine – Water temp min 75°F, 50-99ppm, contact time min. 7 sec

Iodine – Water temp min 68°F, 12.5-25 ppm, contact time min 30 sec

Quats – Water temp min 75°F, less than 500 ppm, contact time min 30 sec

23

How and When to Clean and Sanitize

How to clean and sanitize

1. Scrape or remove food bits from the surface

2. Wash the surface

3. Rinse the surface

4. Sanitize the surface

5. Allow the surface to air-dry.

Food-contact surfaces must be cleaned and sanitized:

After they are used

Before working with a different type of food

Any time a task was interrupted and the items

may have been contaminated

After four hours if the items are in constant use

Cleaning and sanitizing stationary equipment:

Unplug the equipment

Take the removable parts off the equipment

Scrape or remove food from the equipment

surfaces

Wash the equipment surfaces

Rinse the equipment surfaces with clean water

Sanitize the equipment surfaces

Allow all surfaces to air-dry

Put the unit back together

Clean-in-place equipment:

Equipment holding and dispensing TCS food must be cleaned and sanitized every day unless otherwise indicated by

the manufacturer

Check local regulatory requirements

Machine Dishwashing

High-temperature machines:

Final sanitizing rinse must be at least 180°F (82°C)

165°F (74°C) for stationary rack, single-

temperature machines

Chemical-sanitizing machines:

Clean and sanitize at much lower temperatures

Follow the temperature guidelines provided by

the manufacturer

Dishwasher Operation Guidelines:

Clean the machine as often as needed

Scrape, rinse, or soak items before washing

Use the correct dish racks

NEVER overload dish racks

Air-dry all items

Check the machine’s water temperature and

pressure

Manual Dishwashing - Three-Compartment Sinks

Setting up a three-compartment sink:

1. Clean and sanitize each sink and drain board

2. Fill the first sink with detergent and water at least

110°F (43°C)

3. Fill the second sink with clean water

4. Fill the third sink with water and sanitizer to the

correct concentration

5. Provide a clock with a second hand to let food

handlers know how long items have been in the

sanitizer

24

Using a three-compartment sink:

1. Rinse, scrape or soak items before washing them

2. Wash items in the first sink

3. Rinse items in the second sink

4. Sanitize items in the third sink

5. Air-dry items on a clean and sanitized surface

Storing clean and sanitized tableware and equipment

Store them at least six inches (15 cm) off the floor

Clean and sanitize drawers and shelves before

items are stored

Store glasses and cups upside down on a clean

and sanitized shelf or rack

Store flatware and utensils with handles up

Cover the food-contact surfaces of stationary

equipment until ready for use

Clean and sanitize trays and carts used to carry

clean tableware and utensils

Cleaning

When cleaning the premises: Clean nonfood-contact surfaces regularly. This includes floors, ceilings, walls, equipment

exteriors, etc.

Cleaning up after people who get sick: Diarrhea and vomit in the operation must be cleaned up correctly. Correct cleanup

can prevent food from becoming contaminated and keep others from getting sick

Chemical Storage

Storing cleaning tools and chemicals: Place in a separate area away from food and prep areas

The storage area should have:

Good lighting so chemicals can be easily seen

Utility sink for filling buckets and washing cleaning tools

Floor drain for dumping dirty water

Hooks for hanging cleaning tools

NEVER:

Dump mop water or other liquid waste into toilets or urinals

Clean tools in sinks used for: hand washing, food prep or dishwashing

Chemicals:

Only purchase those approved for use in foodservice operations

Store them in their original containers away from food and food-prep areas

If transferring them to a new container, label it with the common name of the chemical

Keep MSDS for each chemical

When throwing chemicals out, follow instructions on the label and local regulatory requirements.

25

Develop a Cleaning Program

To develop an effective cleaning program:

Create a master cleaning schedule

Train your staff to follow it

Monitor the program to make sure it works

To create a master cleaning schedule, identify:

What should be cleaned

Who should clean it

When it should be cleaned

How it should be cleaned

Monitoring the cleaning program:

Supervise daily cleaning routines

Check cleaning tasks against the master schedule every day

Change the master schedule as needed

Ask staff for input on the program

Additional things you may need to know…

Q. What are the 3 Government agencies that deal with food?

Answers.

The Food and Drug Administration (FDA)

U.S. Department of Agriculture (USDA)

Centers for Disease Control and Prevention (CDC)

Food and color additives:

Only use additives approved by your local

regulatory authority

NEVER use more additives than are allowed

NEVER use additives to alter the appearance of

food

Do NOT sell produce treated with sulfites before it

was received in the operation

NEVER add sulfites to produce that will be eaten

raw